About ASM

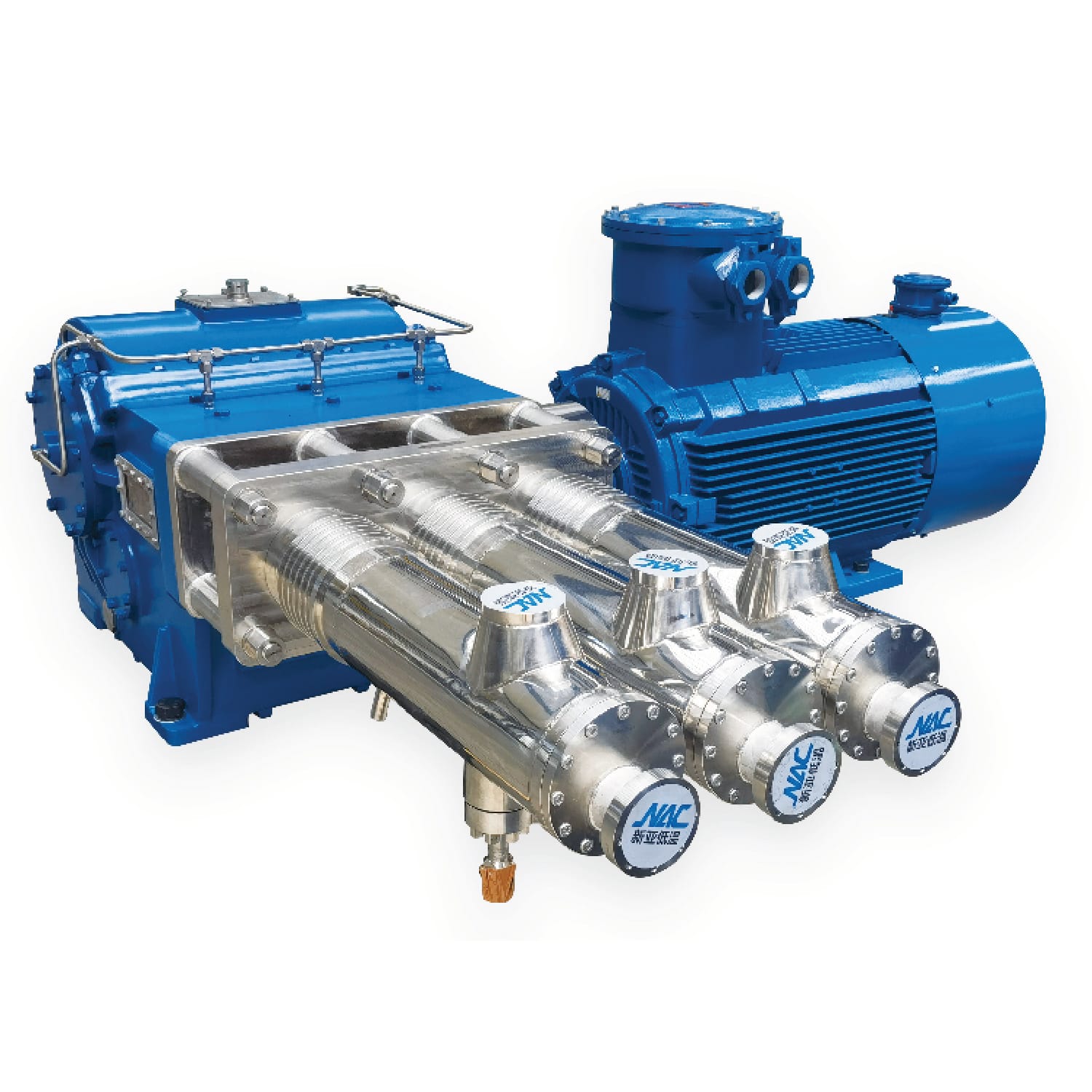

Asia Smart Manufacturing (ASM) is an export division of a leading Chinese manufacturer of pumps for LNG, cryogenic and chemical industries, also specializing in reverse engineering of rotating equipment in a wide industrial field.

Our integrated Engineering Team with Chinese and Russian engineers is a coherent professional team that experienced in a design as in Russia, as in China.

Why ASM?

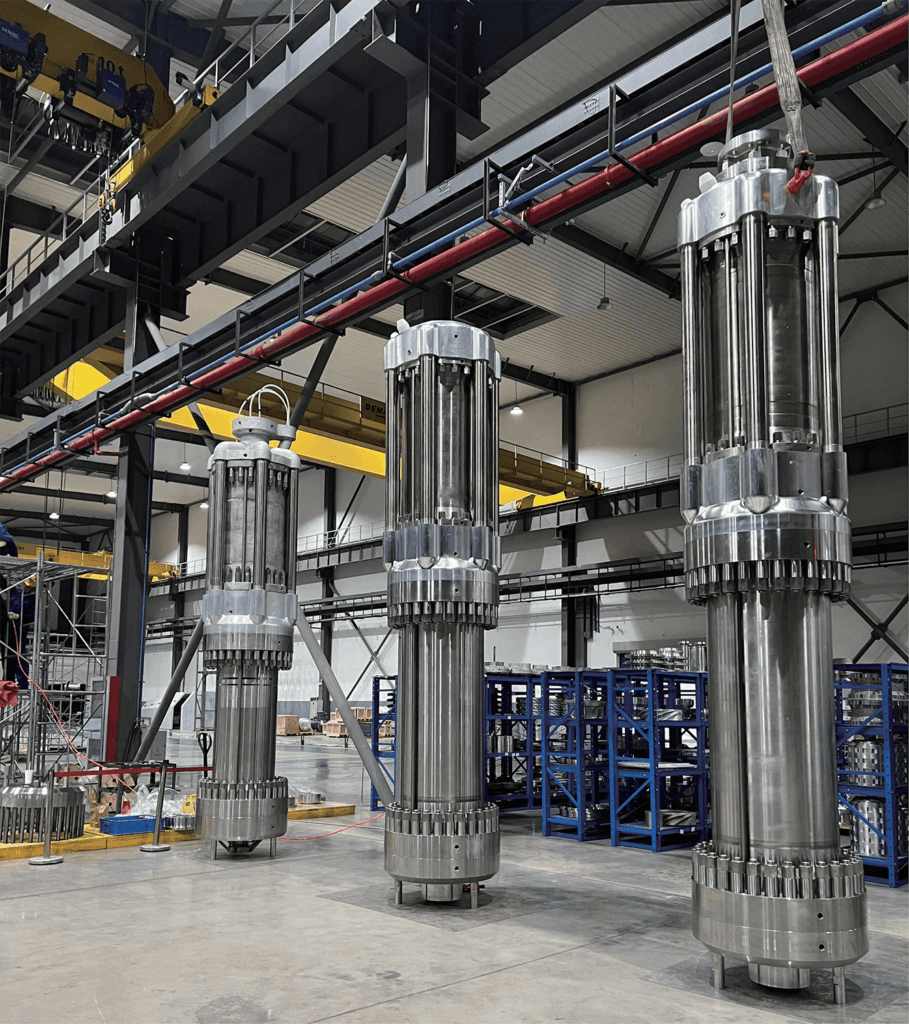

Our new production facilities put into operation in 2021 (brief description – 20,000 m2 of area, 3,000 m2 of “clean room” for the assembly of critical pumps and medium and high pressure oxygen pumps).

The production capacity ensures the release of 500 pumps per year, and the engineering team has already implemented professional scientific research and patents.

Products

Over the past 5 years, our engineers and designers have successfully established and implemented maintenance & revamping technology, as well as a full replacement on a “Plug & Play” principle of high-pressure and process pumps manufactured by leading European manufacturers such as (Cryostar, Cryomech, ACD).”

Projects for pumps replacing have been successfully implemented in China, Malaysia and Russia.

One-Stop Delivery

Our integrated engineering team with Chinese and Russian engineers is a coherent professional team that experienced in a design as in Russia, as in China.

A unique engineering team approach with a high precision CNC’s and advance software makes true a very complex tasks and challenges.

The experience of the engineering team allowed us to find a unique approach to interaction between the customer’s service, adaptation of needs and effective interaction with the Chinese side, which, relying on a high-tech production base, allows us to achieve high results in the most difficult tasks.

This approach has proved its effectiveness over the past 2 years of successful work with Russia.

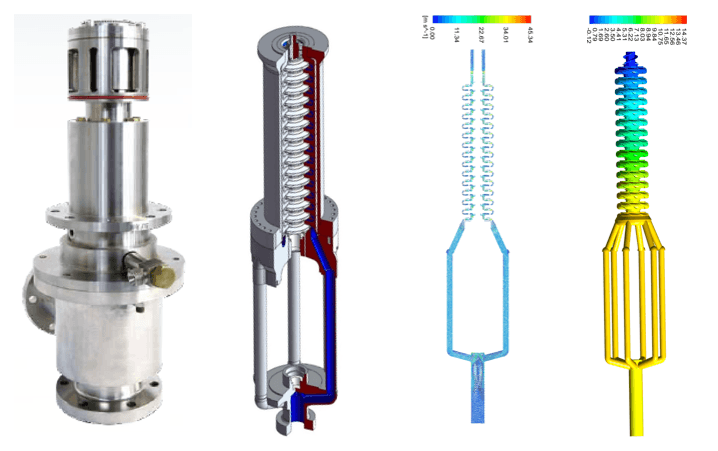

In more details – approach of our team of engineers and technologists to the reverse engineering process is – “a verified engineering product, instead of an exact geometric copy”.

A wide network of partnerships in China allows us to attract experts from leading institutes and industries to verify calculations and technical solutions.

At each stage of product manufacturing, experts simulate the product’s operation based on the calculated parameters of the original sample and the measurements taken. The measured model is adjusted without affecting the final connection and overall dimensions. This deep engineering approach allows us to guarantee the achievement of the operational characteristics of the equipment as a whole when using parts and assemblies manufactured by reverse engineering.

Innovation and research

Our company is one of the leaders in China in innovation and scientific developments. We widely cooperate with the aerospace agency, research institutes and laboratories.

Constant innovations allow us to improve our products and achieve high results.

One of the latest developments in partnership with the aerospace agency is the Liquid Helium Pump.

Application

Workshop Layout

Expertly arranged to cater to the specialized production processes, focusing primarily on precision machining and quality control. The plant is equipped with advanced production and measurement equipment, each allocated its specific zone to optimize workflow and ensure the highest standards of quality.

Production Equipment

The latest-generation five-axis machining center located in HEARMEL, Germany, and MIKRON, Switzerland, accommodates various machining profiles and offers exceptionally high precision.

Measurement Equipment

Asia Smart Manufacturing Co., Ltd

Shanghai Free Trade Zone

We will respond to your inquiry within one business day!